Hongrun machinery Scrap Steel Crushing Line

Description of Scrap Steel Crushing Line

Description of Scrap Steel Crushing Line

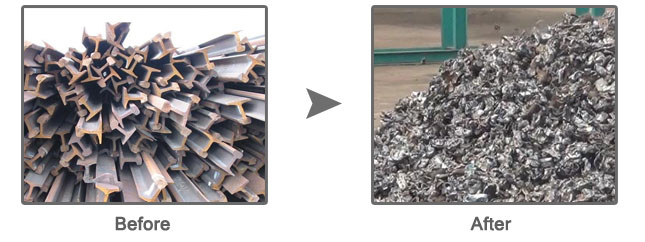

The scrap steel crushing line is designed for the processing of scrap car bodies, tinplate, discarded appliances, bicycles, refrigerators, steel tile, metal cans and other metal scrap. This line has the features of high grinding efficiency, uniform discharging particles with lumpy shapes. It is easy to transport, also enhance the dissolution rate. Scrap steel crusher is driven by geared motor which is power saving 20%. The blades of the scrap steel crusher adopts intermeshing design and made of high-alloy which has good effect on high hardness materials such as unsorted mixed low quality scrap metal and scrap cars, briquettes, bicycles, motorcycles, etc.

Working Principle

Working Principle

High-speed rotating hammer crushing can peel off the surface rust, paint and dirt of the scraps.

High-speed rotating hammer crushing can peel off the surface rust, paint and dirt of the scraps.

After crushing, the scraps are processed by vibrating conveyor, belt conveyor and magnetic separation systems. The iron, non-ferrous metal and non-metallic materials (such as plastic, rubber) are separated and conveyed by respective conveyors. It can not only get the crushed steel block (size is adjustable), but also get the non-ferrous metals through artificial selection. The bulk density of crushed scrap steel can be 1.2t/m3, is ideal electric steelmaking furnace charge.

After crushing, the scraps are processed by vibrating conveyor, belt conveyor and magnetic separation systems. The iron, non-ferrous metal and non-metallic materials (such as plastic, rubber) are separated and conveyed by respective conveyors. It can not only get the crushed steel block (size is adjustable), but also get the non-ferrous metals through artificial selection. The bulk density of crushed scrap steel can be 1.2t/m3, is ideal electric steelmaking furnace charge.

Ferrous and non-metallic material are selected again by magnetic device on the conveyor, free iron metal is picked out, thus to improve the iron recovery. Non-ferrous metals can be selected through artificial selection.

Ferrous and non-metallic material are selected again by magnetic device on the conveyor, free iron metal is picked out, thus to improve the iron recovery. Non-ferrous metals can be selected through artificial selection.

Application of PSX-80104 Scrap Steel Crushing Line

Application of PSX-80104 Scrap Steel Crushing Line

Squashed or not squashed whole car with or without engines;

Squashed or not squashed whole car with or without engines;

Cutting or packing pocessed thin materials with density not more than 1t/m3;

Cutting or packing pocessed thin materials with density not more than 1t/m3;

Scrap steel plates with thickness less than 6mm, width less than 2.6m, length less than 5m;

Scrap steel plates with thickness less than 6mm, width less than 2.6m, length less than 5m;

Household appliances such as air conditioners, washing machines, refrigerators and so on.

Household appliances such as air conditioners, washing machines, refrigerators and so on.

Materials that can NOT be processed:

Steel cable with diameter more than 22mm, length more than 7.5m;

Steel cable with diameter more than 22mm, length more than 7.5m;

Alloy steel shaft with diameter more than 25mm;

Alloy steel shaft with diameter more than 25mm;

Mild steel shaft with diameter more than 37mm;

Mild steel shaft with diameter more than 37mm;

Board with thickness over 20mm, length more than 300mm;

Board with thickness over 20mm, length more than 300mm;

Board with thickness over 25mm, length more than 150mm;

Board with thickness over 25mm, length more than 150mm;

Structural Profiles with cross-section more than 12.5mm;

Structural Profiles with cross-section more than 12.5mm;

Steel bars with diameter greater than 40mm;

Steel bars with diameter greater than 40mm;

High carbon steel round bar with diameter greater than 12mm;

High carbon steel round bar with diameter greater than 12mm;

Ingots, billets and similar materials, etc.

Ingots, billets and similar materials, etc.

For materials that can not be broken, there is discharge door in the upper part of the crusher to protact protect the machine. Users can quickly open the discharge door, so that the materials that can not be broken are ejected from the crusher.

whatsapp:008613937134928