Shredding Machine

Mobile/WhatsApp: 008613592505674

http://www.vidacrusher.com

►1. Product Description:

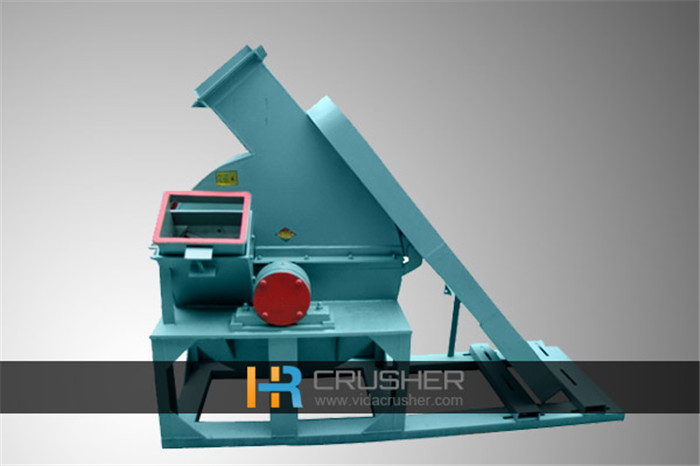

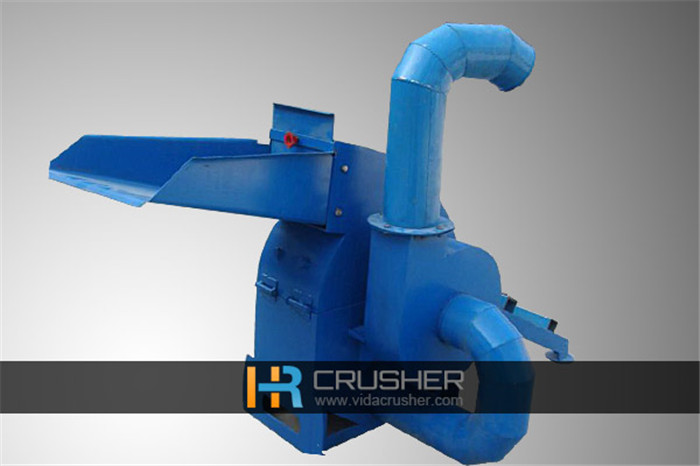

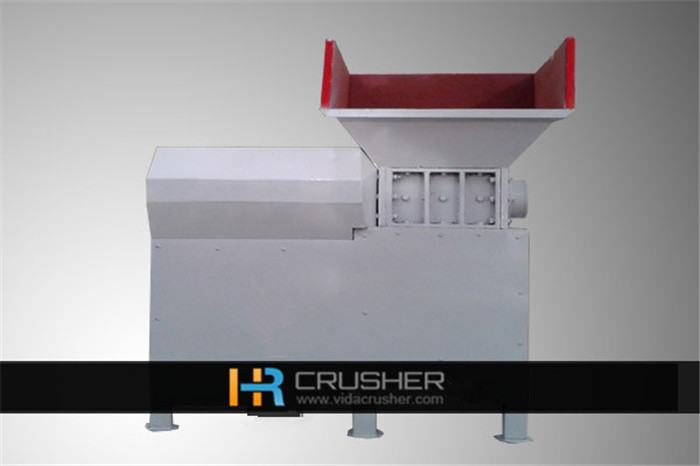

People's living standards gradually increased, more and more garbage, for the second use of waste, Hongrun specially launched various models of shredders. Raw materials can be scrap metal, wood, rubber, plastic, etc., to provide a variety of shredders, according to the finished product size, texture, size and yield of customers choose the appropriate model; shredder is the most advanced metal smash Equipment, the series of shredders in the absorption of a variety of advantages on the basis of the full use of impact, shear, high-speed impact, mutual grinding and other principles carefully developed, after years of continuous practice in the same industry-leading equipment level. We would like to first-class technology to create first-class products, to provide you with warm and thoughtful service.

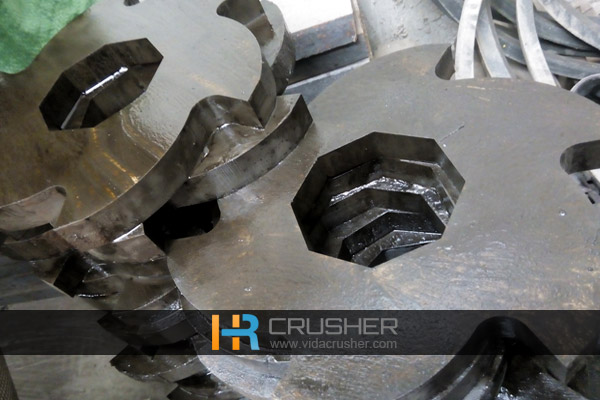

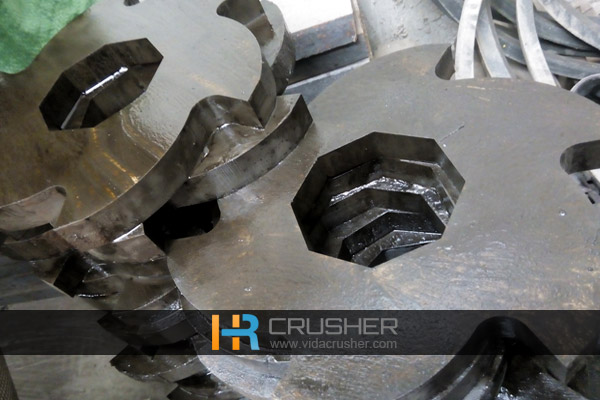

►2. Composition of shredder:

The shredder is mainly composed of chopped blades, cabinets, cabinet supports, feeding systems, power systems and electrical control systems. The shredder is used to treat large volumes of material with high strength to increase its bulk density for further transport and recycling.

►3. Shredder working principle:

The material is fed into the chopper cabinet through the feed system and is adequately treated by the combined effect of tearing, cutting and extrusion. The large material is cut into pieces and discharged from the lower part of the pulverizer. The difference between the grinder and the hammer crusher is that the pulverizer has a wide feed port and is easy to feed the feed, with the advantages of low tool speed, low noise and low energy consumption.

►4. Application of shredder:

Mainly used for broken metal oil tank, oil drums paint cans, beverage cans, paint cans, paint cans, pure water bottle metal, Wang Laoji cans, six walnut cans, paint cans, red cans, Harbin beer cans, Qingdao beer cans , Etc. etc. These iron, aluminum packaging bottles and so on. At the same time can also waste copper, waste bicycles, scrap motorcycles, scrap cars, aluminum plastic waste, briquettes and other crush the ideal shape.

►5. Shredder equipment features:

1) Conveyor equipment can be configured.

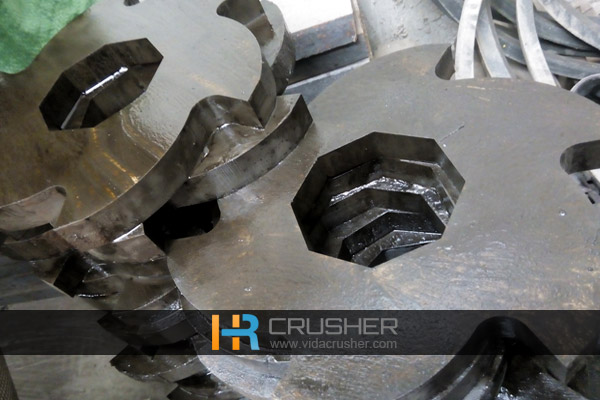

2) shredder equipment blade with meshing blade, the blade is made of high alloy refined, very tough, it can be said to cut iron as mud.

3) The new shredder equipment is simple to operate, the whole process of a person can operate a shredder equipment.

4) strong shredder equipment body structure, dense stiffening board, to ensure that the fuselage strong.

5) shredder equipment configuration is complete, aluminum and iron together when the powder can be effectively separated.

6) gear motor drive.

7) new shredder equipment boot without too much noise.

►6. Shredder maintenance:

1) timely check clean up, after the end of work every day, should promptly clean the machine, check the various parts of the screw with loose and claw, sieve and other wearing parts of the wear and tear situation.

2) filling grease, the most commonly used in the bearing on the assembly of oil cups. Under normal circumstances, as long as every 2 hours to rotate the oil cup cover 1/4 turn, the cup grease can be pressed into the bearing. In the case of closed bearings, grease may be added once every 300 hours. After long-term use, grease if modified, should be clean bearings, for the new grease. Machine work, the bearing temperature shall not exceed 40 ℃, such as in normal working conditions, the bearing temperature continues to increase, you should find out the reasons, try to troubleshoot.

3) carefully washed to be crushed raw materials, is strictly prohibited mixed with copper, iron, lead and other metal parts and larger stones and other debris into the crushing chamber.

4) Do not arbitrarily improve the speed of the shredder, the general allowable and rated speed difference of 8% -10%. When the shredder and the larger power machine supporting work, should pay attention to control the flow, and make the flow evenly, can not be quickly and slowly.

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher