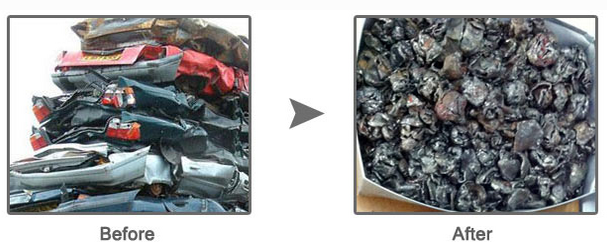

Car Shell Shredder

Mobile/WhatsApp: 008613592505674

http://www.vidacrusher.com

►1. Product Description:

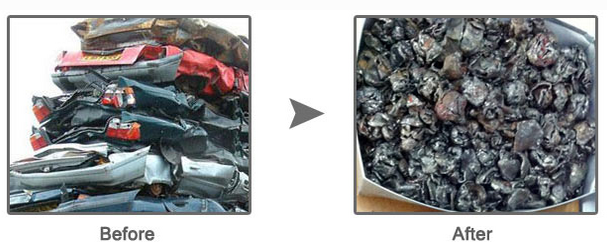

Car shredder (crusher), shredded blade group crusher, transport box, box bracket, feeding system, power system, electrical control system. The car shredder is a large biaxial shredder device. Is my company for scrap metal, metal, alloy, aluminum and other scrap metal production of metal crusher. As a domestic production of scrap metal scraping equipment manufacturers, with many years of actual production experience and technical guidance.

►2. Applicable materials:

Cars, iron, bicycles, motorcycles, cars, pig iron, fine iron, Lulu cans, diesel drums, refrigerators, air conditioners, waste electrical appliances red iron cans, scrap aluminum, scrap copper, iron drums, car racks, metal scrap , Tires, rubber, wood and other scrap metal.

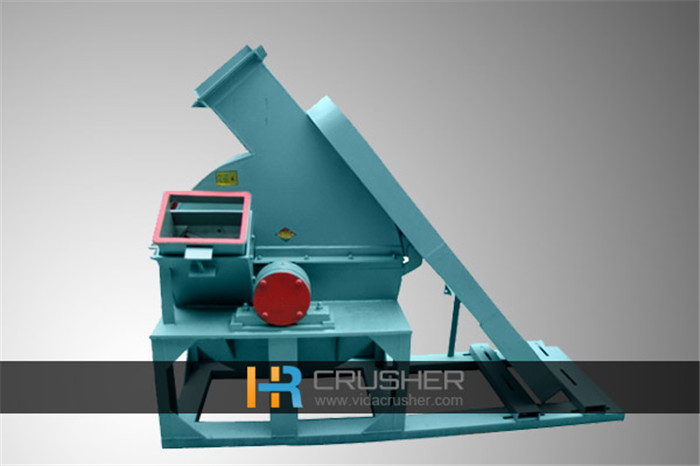

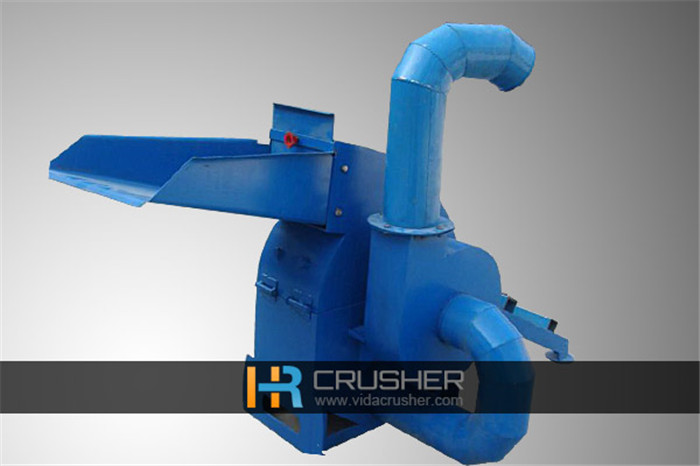

►3. Car shredder structure:

Car shredders mainly by the tearing blade group, carrying the box, the box bracket, feed system, power system, electrical control system composed of the machine. Mainly used for shredding a certain strength of light metal, increasing its bulk density in order to facilitate the transport, recycling.

►4. Product advantages:

►4. Product advantages:

Waste carcass and car metal are crushed into smaller groups of particles. Reduce the amount of raw materials to make it mixed with other materials. The crushed material is easier to store relative to the non-crushed material, saving a lot of warehouse space, greatly facilitating the use and post-processing.

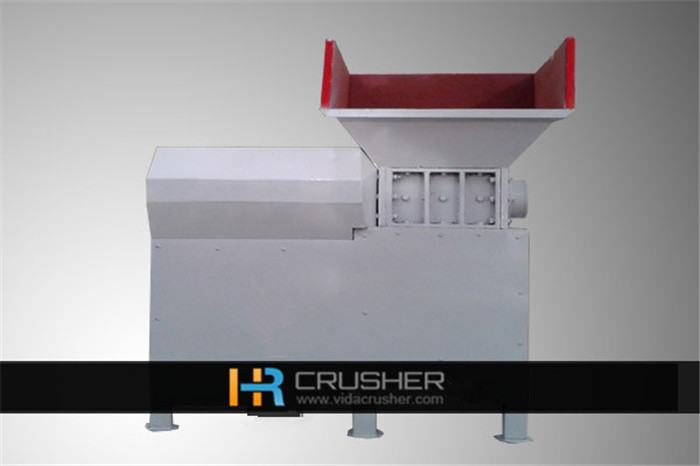

►5. Equipment features:

1) thick knife, high crushing power, tools are used special steel through forging production and processing, strong use of long life.

2) The fuselage is made of high strength steel plate welding, can be anti-high torque, the body is very durable.

3) the use of microcomputer (PC) automatic control, set the start, stop, reverse and overload automatic reversal control.

4) equipment with low speed, high torque, low noise, dust can meet the characteristics of environmental standards.

5) easy to adjust, low maintenance costs, economic and durable.

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher