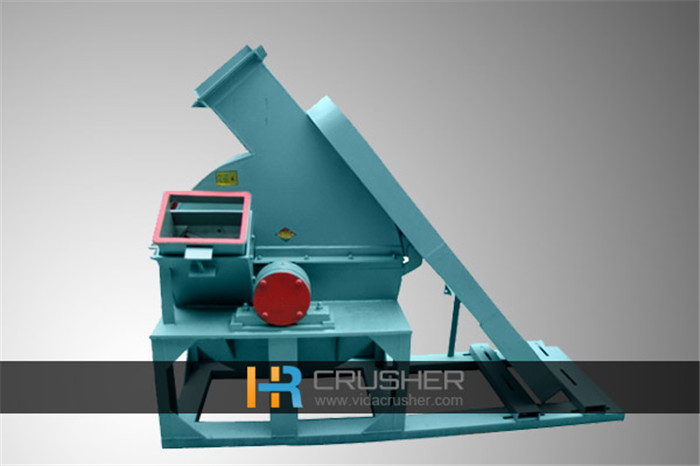

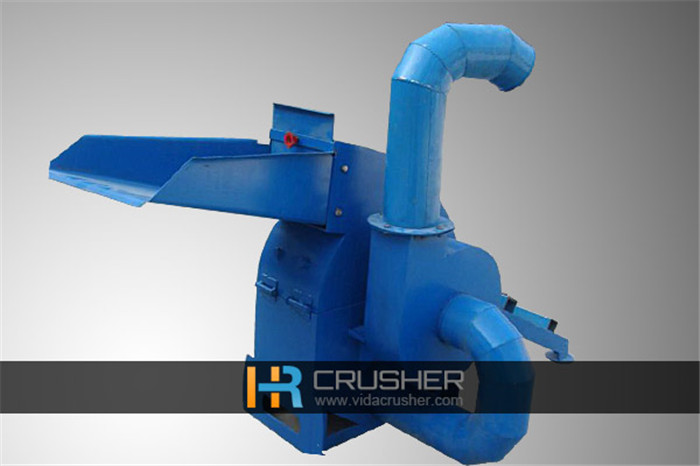

Straw crusher instructions

Straw crusher instructions

1. Crusher long-term operation, should be fixed on the basis of cement. If the working site is often changed, the pulverizer and the motor are to be mounted on the frame made of angle iron. If the pulverizer diesel is powered, the power should be matched, that is, the power of the diesel engine is slightly larger than the power of the pulverizer, The pulley groove is the same, and the outer end of the pulley is on the same plane.

1. Crusher long-term operation, should be fixed on the basis of cement. If the working site is often changed, the pulverizer and the motor are to be mounted on the frame made of angle iron. If the pulverizer diesel is powered, the power should be matched, that is, the power of the diesel engine is slightly larger than the power of the pulverizer, The pulley groove is the same, and the outer end of the pulley is on the same plane.

2. After the installation of the crusher to check the fastening parts of the fastening, if loose to be tightened.

3. To check the belt tightness is appropriate, the motor shaft and shredder shaft is parallel.

4. Before starting the pulverizer, first turn the rotor by hand to check whether the hammer and the rotor are flexible and reliable. Is there any collision in the shell, whether the rotation of the rotor is in the same direction as the arrow on the machine, the motor and the powder machine are lubricated Is it good?

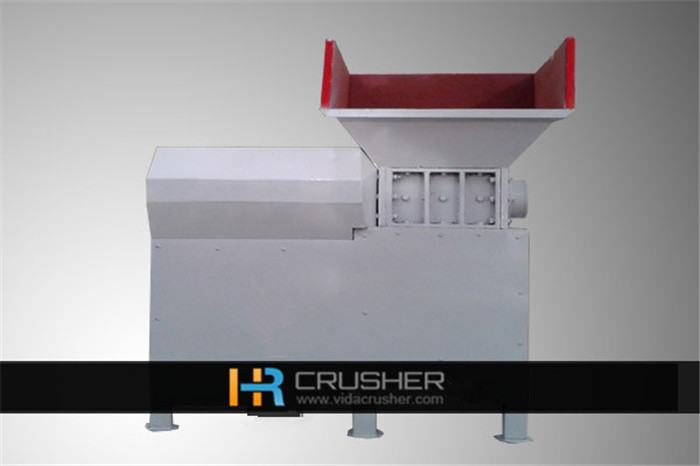

5. Do not replace the pulley casually, to prevent the speed is too high to make the crushing chamber explosion, or the speed is too low affect the work efficiency.

6. After the start of the crushing station idle 2 to 3 minutes, no abnormal phenomenon after feeding work.

7. Work at any time to pay attention to the operation of the grinder, feeding to be uniform, to prevent blocking the car, do not run for a long time overload. If you find a vibration, noise, bearing and body temperature is too high, outward spray and other phenomena, should immediately stop the inspection, troubleshooting can continue to work.

8. Crushed material should be carefully checked to avoid copper, iron, stones and other hard objects into the crushing chamber caused by the accident.

9. Operators to wear gloves, feeding should stand on the side of the pulverizer, to prevent the rebound of debris hit the face.

Mobile:+8613592505674

Email: sales@hwdcrusher.com

Email: sales@hwdcrusher.com

http://www.vidacrusher.com